Investment Casting Services

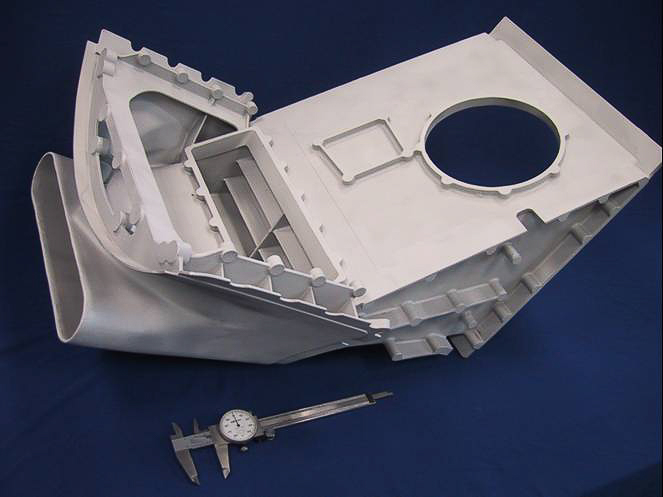

At FastCastingsInc., we offer investment casting services. This process is different from sand casting because we use wax instead of sand to create the molds. Typically, this method results in more accurate surface finishes. In each step, our skilled experts oversee the 3D printing process to ensure quality mold production, which ultimately leads to quality metal casting.

What Is Investment Casting?

Investment casting is a metal-casting process that utilizes a wax mold. Once the metal cast sets, the wax pattern is melted for removal. This industrial process is also known as “lost wax” because the wax mold is lost during execution to reveal the finished product. Lost wax investment casting is one of the oldest known metal-casting techniques. It comes with several benefits you won’t find with other casting methods.

At our investment casting foundry, we utilize printed patterns in our process, so no tooling is necessary. Within days of receiving 3D CAD data, our printed patterns can be readied for metal casting with our 3D printed materials burning out just like wax.

By taking advantage of 3D print technology, we no longer need to waste time producing wax patterns. This speeds up our process considerably, which ensures you receive your finished goods much sooner.

In the traditional investment casting method, manufacturers have to spend time creating wax tooling before casting can begin. This time-saving benefit can help you accommodate tight production deadlines. Printed patterns can also be very cost effective because we can skip the tooling step.

Along with cost savings, investment casting increases accuracy, repeatability, versatility, and integrity, especially when cast in a vacuum. In fact, with printed patterns, geometry that would otherwise be impossible can be accomplished. Complexity is not an issue for our 3D Printed Pattern investment casting services.

If you have any questions about our lost wax investment casting options, let us know. We’re happy to help.