Metal casting doesn’t have to be a guessing game. With state-of-the-art technology, we can evaluate our casting process ahead of time and correct deficiencies. This analysis ensures consistent, quality tooling and parts.

The Importance of Mold Flow Analysis

Traditionally, handmade tools are created, tested, and adjusted until an optimal casting is achieved. This can take weeks, so it’s important to get it right the first time. However, if you invest in casting that produces defective tooling, you’ll wind up spending more time and money to reevaluate the process and create new molds. Advanced mold flow analysis software eliminates this risk by thoroughly testing the process to identify errors early in the process.

At FastCastings, we now use a virtual environment to complete this in-depth melt flow rate testing to determine the effectiveness of a casting’s rigging and mold. When you use our services, you know the tooling will come out the way it should.

Our Mold Flow Analysis Services

We believe in quality execution for our clients, so we apply this process to every mold we create. It’s a crucial step in our design process, so we invest in the best software to produce optimum analysis.

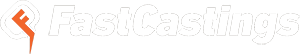

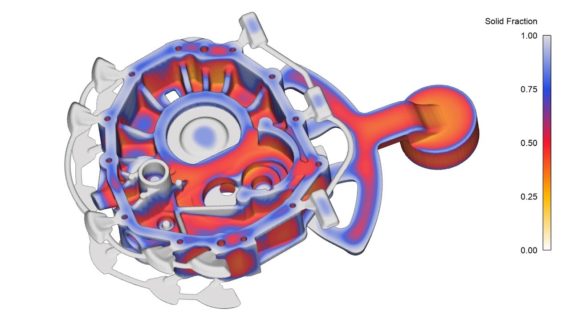

During mold simulation, we test each stage of the metal casting process, which includes pouring and solidification. The software evaluates the mold’s shape and intended casting material to ensure the metal can flow to all parts of the mold. We can also identify the ideal injection pressure and temperature levels to produce the highest-quality results. With this step, we can resolve potential problems before costly tooling is made.

If you have any questions about our mold flow analysis process, let us know. Our goal is to provide our customers with quality output every single time, so we invest in the best resources to create effective casting molds and rigging. Contact us for a quote, or reach out for more information.