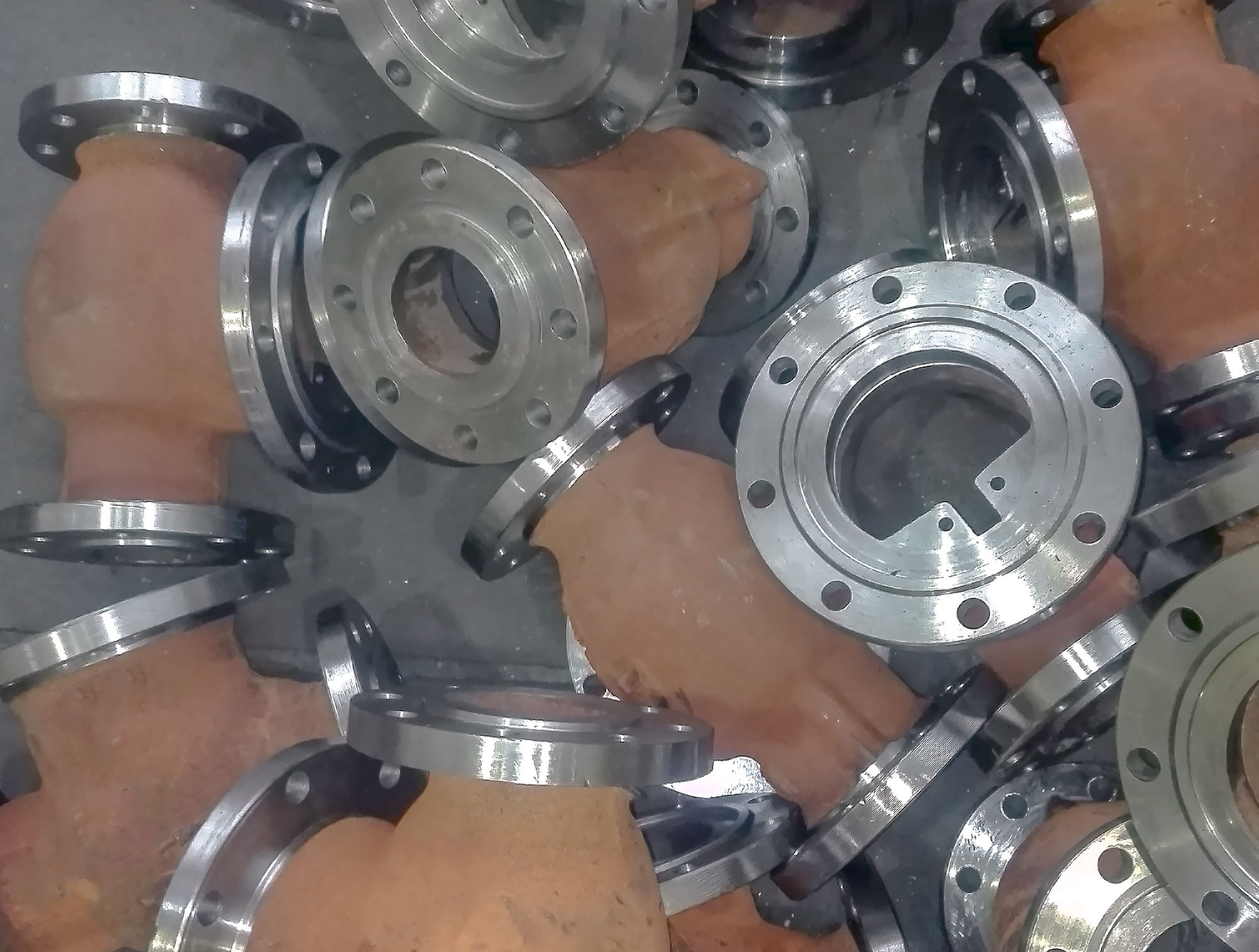

Traditional and Digital Sand Casting Services

At FastCastings Inc., we’re well-versed in all types of sand casting. Our expertise allows us to offer both traditional and digital sand casting services. Although the latter can produce results in a much faster time frame, we guarantee quality results if you opt for the conventional sandcasting process.

Traditionally, sand castings take a half dozen steps after the drawings have been produced. Pattern makers interpret the original design from paper to wood patterns. Once we have this pattern, we pack sand around the model to create a mold. We fill the mold with molten metal, which will cool and harden to produce the finished part. With this type of sand casting, crafting the wood pattern takes the most amount of time. From start to finish, this process can take up to six weeks.

For those who need faster results, we recommend our digital sand casting services. Printed patterns can be ready to produce metal parts within 10 days.

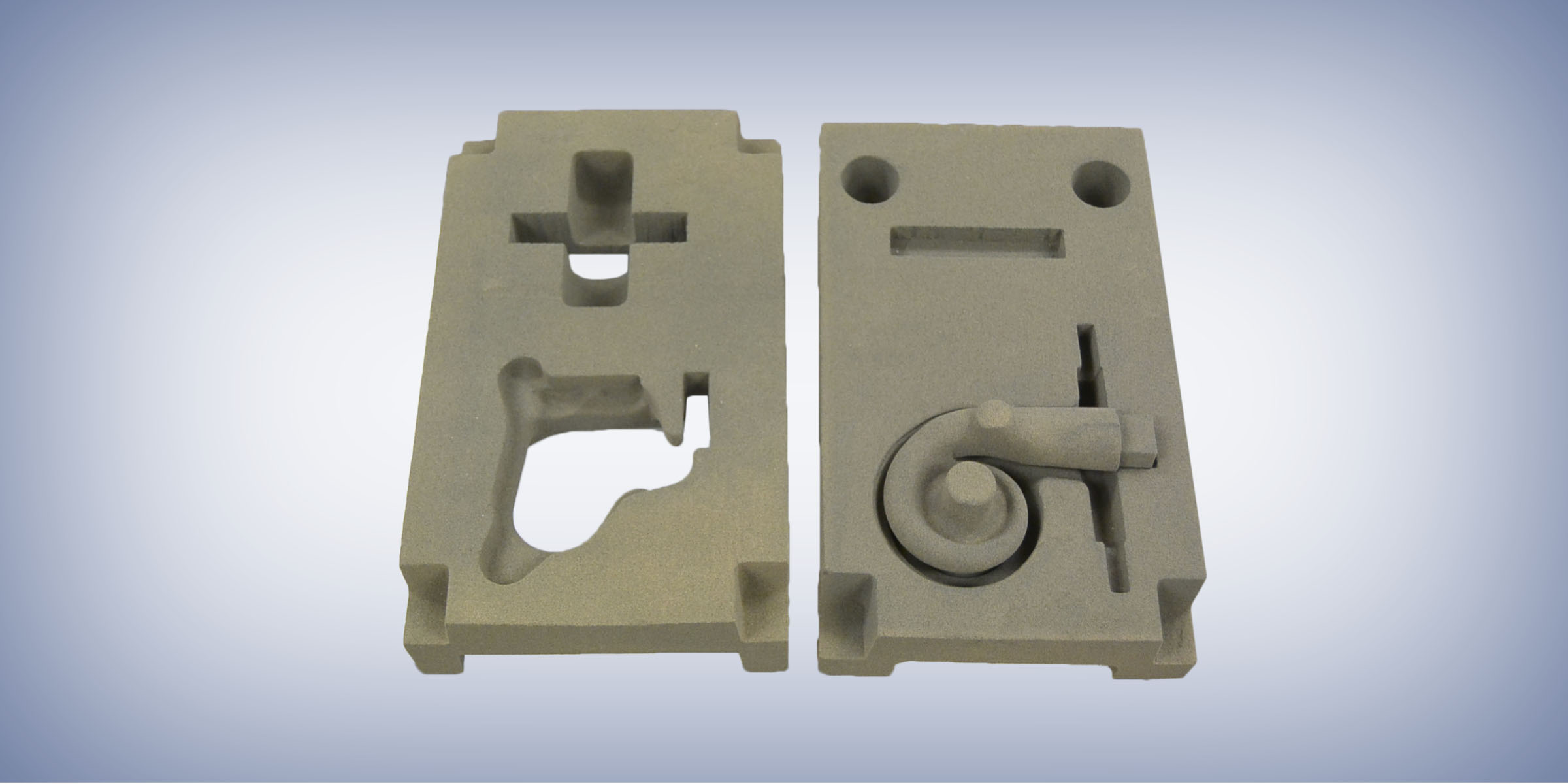

Digital sand casting uses 3D printed sand molds, also known as Fast Castings. These are a direct replacement for the traditional process of creating matchplates and coreboxes for short runs or prototypes, but printed molds also replace large-scale production tooling.

The same timelines exist for production tooling as prototype castings. Within days tooling can be produced. This faster process makes 3D sand casting the ideal choice for manufacturers who need large volume castings quickly.

Cooperation

Our process is flexible, so we can adapt each job to fit the specific project’s requirements. Let us know your needs, and we’ll deliver quality results, whether you request traditional or digital sand casting services. We can produce production castings or, with cooperation from your existing foundry, we can deliver the tooling to them direct.

Contact us today to learn more about our sand casting options. Our team is ready to get to work on your metal casting project!